成果展示

返回马仁杰、董文斌、崔剑锋:齐大刀标准化生产的研究——基于临淄新发现战国晚期铸钱遗存的初步分析

齐大刀标准化生产的研究——

基于临淄新发现战国晚期铸钱遗存的初步分析

马仁杰、董文斌、崔剑锋*

中文梗概

金属铸币的起源和古代经济的货币化长期以来一直是考古学和经济史的研究重点。东周时期,商品经济空前繁盛,金属铸钱开始登上历史舞台,直至被秦半两统一,四百年来的金属货币发展出了种类形制极其复杂的货币体系。然而,关于早期铸钱遗址的最直接的考古信息很少发现。2019年,考古学者在齐国临淄故城的小城西门外地点发现大规模铸钱遗物,初步判断为一处铸钱废弃物堆积坑,这为系统研究战国晚期齐国铸钱业的技术水平和产业规模提供了可能,对于研究秦统一货币之前早期货币的标准化历程至关重要。总之,齐国各时期的金属货币形制特征鲜明,流行时间明确。在这样一个清晰的年代框架之下,窥探齐国金属货币背后的生产背景与流通范围,正是研究齐国经济状况和社会文化的一个很重要的切入点。

综合分析显示,战国晚期齐国铸钱手工业,在冶炼技术、制范工艺、合金配比等生产环节上,遵循相辅相成、环环相扣的发展轨迹。制作钱范采用夹砂灰陶,粉砂含量适中,含有一定粘土成分,热膨胀率明显更低。钱范表面存在均匀的分型涂层。这些都是综合钱币合金配比特征,出于控制产品形变,标准化生产的需求而特别选取的制范工艺。该遗址存在冶炼含硫铜铅矿石得到冰铜,并加入锡料进行合金化的工艺,或许还存在冰铜精炼后,加入锡铅原料配制合金的过程,这样的冶炼技术能够大幅提高铜铅合金的生产效率。

炉渣、钱范和“齐大刀”基本都属于一类相同的高比值铅,这是山东半岛地区首次确证的利用这类铅资源的冶铸遗物。以上分析进一步明确战国时期齐国铸钱铅料来源的演变与合金成分的变迁高度同步。个别铸钱遗物的资源特征与燕明刀十分接近,亦符合辽东地区铅矿的特性。不排除齐国最开始使用的高比值铅原料来自于本地,而部分高铀铅原料或许在燕据齐地之后才出现。总之,以上分析充分揭示出战国晚期“齐大刀”的生产具有高度的标准化,表现在其冶炼技术高效便捷、制范工艺统一稳定、产品材质均匀一致,矿料来源相对固定。统一化、标准化的铸钱生产,正是田齐时期垄断货币铸造权、发展商品经济的直观体现。

* 北京大学考古文博学院崔剑锋教授(cuijianfeng@pku.edu.cn)、山东省考古所董文斌副研究员为论文通讯作者,学院博雅博士后马仁杰为第一作者。该研究得到国家重点研发计划(2022YFF0903702)的资助。

本文于2024年3月11日发表于Archaeological and Anthropological Sciences,中文梗概仅用于推介,引用请参考英文原文。Ma, R., Dong, W. & Cui, J. Standardization production of Qi Knives: A comprehensive analysis of the minting remains of knife money unearthed in ancient Linzi in the late Warring states period. Archaeol Anthropol Sci 16, 52 (2024). https://doi.org/10.1007/s12520-024-01955-0

Introduction

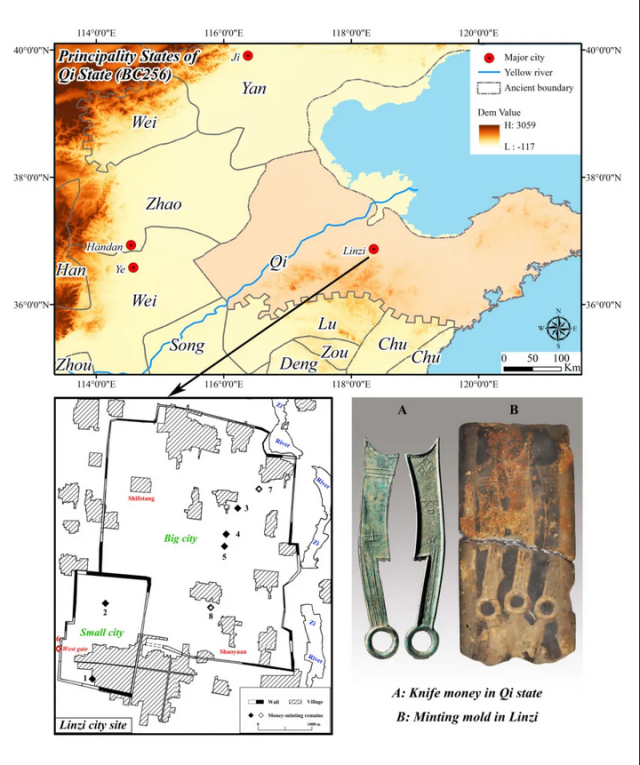

The Eastern Zhou Dynasty period (770-221BC) marked a significant period of profound social transformation in ancient Chinese history. The commodities economy had an extraordinary period of growth, accompanying by the emergence of metal currencies especially bronze currencies. The origins of metal coinage and the monetisation of ancient economies have long been a research focus in both archaeology and economic history (Figueira 1998 & Schaps 2004). However, the most direct archaeological information on early minting sites is scarce. The recent outstanding work of Guanzhuang site (640-550 BC) has already confirmed that China has the world's oldest-known, securely dated minting site (Zhao et al. 2021). Over the years, systematic investigations (SPICRA 2013) conducted in the Linzi city site of Qi state have yielded a large amount of minting remains for casting knife money (Fig. 1) in the late Warring states period (around 300-221BC), which is crucial for future research on the further development of early standardized coinage before Qin empire's unification of currency (Wu 2005).

Linzi, the ancient capital city of Qi state is always portrayed as a prosperous metropolis with a significant level of economic affluence in the historical records of "shiji". The prevalent metallic currencies circulated within the Qi state encompass knife money and round money. The special knife money exhibits a striking resemblance to the physical form of knives that were commonly employed throughout the Zhou dynasty. Qi knives are commonly categorized based on the amount of characters present in their inscriptions, such as Three Character Knives, Four Character Knives, and so forth. Archaeological evidence mainly supports that the production period of knife money is concentrated in the Warring states period (Wang 1988). It is commonly considered that the minting date of Four or Five Character Knives are expected to be in the early and middle Warring states period, while Three Character Knives are supposed to be in the late Warring states period. Ming knives of Qi state, which have a striking resemblance to the Ming knives of Yan state, are widely believed to have originated during the period of Yan's conquest (284-279 BC) (Wang 2005). During the final stages of the Warring states period, there was a popularity of a certain type of round money circulated within the Qi state.

It is urgent to systematically investigate the overall layout of the minting industry of Qi state and reveal more technical backgrounds. The book “Archaeology of metallurgy and foundry industry in the Linzi City site of Qi state” elucidated the correlation between the transformation of the foundry industry's layout and the development of capital structure and function (CASS et al. 2020). The archaeological remains of minting industries during the Warring states period were particularly notable within the small city. Conversely, in the Western Han Dynasty, these minting remains were predominantly dispersed throughout the big city. Currently, it is evident that during the late Warring states period, the Linzi City site had established a comprehensive industrial chain encompassing copper smelting, lead smelting, bronze alloying, and casting. The scale production of bronze currencies and mirrors in Qi state has been somewhat encouraged by this industry layout and technical backgrounds.

The specific technical characteristics of the smelting and casting industry in Linzi city site are briefly described as follows. In 2021, Dai presented the findings of their investigation on the slags discovered at the west gate of small city, specifically focusing on the technical attributes of smelting sulfur-containing copper-lead ore (Dai et al. 2021). The analysis results of slags discovered in Shaoyuan Village and Shifotang Village had a significantly higher content in iron oxide compared to typical melting slag and these slags should be more accurately referred to as smelting slag, despite the lack of clarity regarding the specific type of product (Du et al. 2012 and Li et al. 2014). As for the molding technology, it seems that the craftsmen of Qi state have developed several different ways to improve the plasticity of pottery mold, which are specially used for casting bronzes with specific alloys and functions. As far as the minting industry is concerned, molds of Three Character Knives in the Warring states Period usually have higher clay content, and molds of Banliang and Wuzhu in the Western Han Dynasty once used talc molds and metal molds instead of pottery molds (Chen 2018 and Yang 2021), all of which should be out of the purpose of controlling casting shrinkage and standardized production. In contrast, the mirror production of Linzi in the Western Han Dynasty tends to pursue the details of decorative patterns, and a large amount of rice husk ash is added to improve plasticity and increase air permeability (Liu et al. 2005 and Cui 2020). This should be a completely different molding technique compared to the minting industry.

In a word, the metal currency of Qi state in different periods have distinct shapes. Under such a clear chronological framework, it is very important to study the economic situation and social culture of Qi state by focusing on the production background and circulation scope behind the metal currency. However, the past research on Qi currency was limited to the component analysis of metal money. There is a lack of systematic archaeo-metallurgical research as the bronze mirror handicraft industry in the Han Dynasty. In 2019, for the first time, a large-scale minting remains (Fig. 1) was found in the west gate of the small city of Linzi (Fang et al. 2021). This made it possible to systematically study the technical level and industrial scale of the minting industry of Qi state in the late Warring states period.

Fig.1 Qi state in the late Warring states period and major minting remains found in Linzi city site

Materials and Methods

Materials

In the year 2021, we had the opportunity to engage in field sampling of the minting remains discovered outside the west gate of the Linzi city site of Qi state. Our investigation primarily focused on the analysis of metallurgical artefacts, including slags, molds, and blowpipes. This site is the only high-class architectural site outside the west gate of Qi capital in the Warring states period, and the western part of the site is generally overlapped by the minting remains. Among the artefacts discovered, a significant portion comprises around 2500 pottery molds engraved with the inscription “Qi Da Dao (齐大刀)”. This discovery represents the greatest assemblage of minting molds recovered in China during the pre-Qin period. The excavator posited that this site was maybe abandoned during the late Warring states period and repurposed as a workshop for minting currency. Furthermore, it was suggested that the function shift of this site may have been influenced by significant historical events.

A total of 12 mold samples, 3 blowpipe samples and 5 plate slag samples were collected for analyses (Fig. 2). Preliminary observation shows that the mold samples are all grey pottery mixed with finely granulated sand. Most of the mold samples have finger pits on the back, and the cavity surface of the mold has obvious traces of casting. The majority of the slag samples have a plate-like structure characterized by a thickness ranging from around 1 cm to 3 cm. Numerous cylindrical pottery artefacts resembling blowpipes, measuring approximately 10 cm in diameter, have also been discovered. The blowpipes exhibit serious burning on both their inner and outer surfaces, accompanied by the presence of many pores in the cross-section.

Fig. 2 Minting remains unearthed outside the west gate of Linzi city site

Methods

All the testing took place at School of Archaeology and Museology, Peking University. We studied the chemical composition of the mold samples using ED-XRF (Horiba XGT 7000) with an X‐ray spot diameter of 1.2 mm, X‐ray tube voltage of 30 kV, data acquisition time of 100 s, glass standard of Coring-D.

Each sample was cut into two parts for mounting and dissolution. The sample for mounting was cold mounted in epoxy resin and then ground and polished with a Struers Tegramin-20 polish-grinding machine. The slag samples were first observed with an optical microscopy at a lower magnification, and then combined with SEM-EDS for further analysis. Slag samples were detected with the Hitachi TM3030 SEM and a Bruker Quantax70 spectrometer. The chemical analysis was standardless, the accelerating voltage was 15 kV, and the collecting time was 70s.

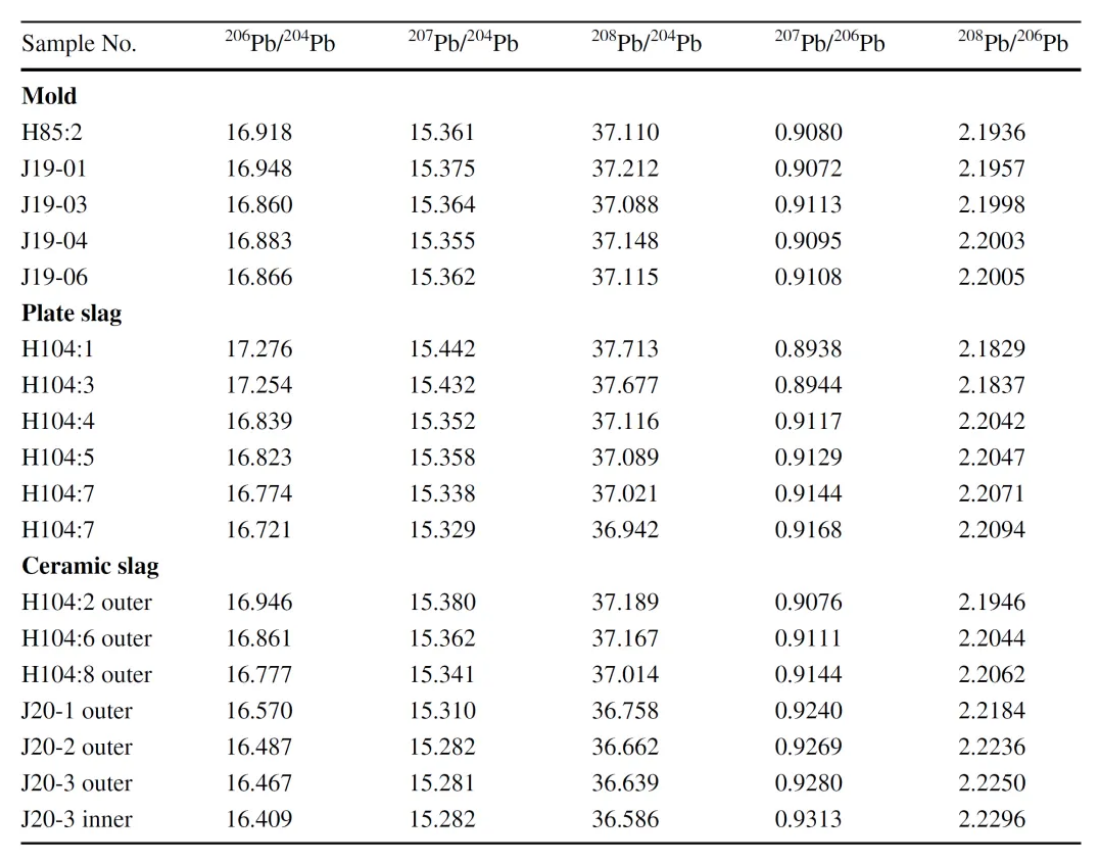

The slag and mold (residue metal) samples for dissolution was first decontaminated and then dissolved in aqua regia. The lead isotope ratios were measured with a VG Elemental multi collector–inductively coupled plasma mass spectrometer (MC-ICP-MS) (VG Elemental Axiom, Thermo Fisher Scientific Inc., USA). An SRM981 standard was used to calibrate the mass spectrometer. Precision and accuracy were assessed with SRM981 after every 6-8 tests. The analytical precisions (RSD) based on SRM981 at 1000 ppb Pb were 0.014% for the 207Pb/206Pb ratio, 0.058% for the 208Pb/206Pb ratio and 0.017% for the 206Pb/204Pb ratio, as given below (Table 1).

Table 1 Parallel test results of SRM 981, analytical error and published values are shown

In addition, Raman spectroscopy and thermal expansion analysis are also used to detect mold samples. Raman spectra were collected at room temperature using a XploRA PLUS spectrometer (Horiba, France) under the 532 nm excitation line. The laser beam was focused by 100×objective lens and a 1 µm diameter laser spot was achieved. A laser power of 1 mW was employed and acquisition time for each spectrum was 100s. The thermal expansion curve of samples were measured by a horizontal differential thermal dilatometry (TA DIL 806) with a heating rate of 7.0 K/min from room temperature up to around 1100 ℃. The size of sample for the thermal expansion analysis is 10.0 mm × 5.0 mm × 5.0 mm.

Results

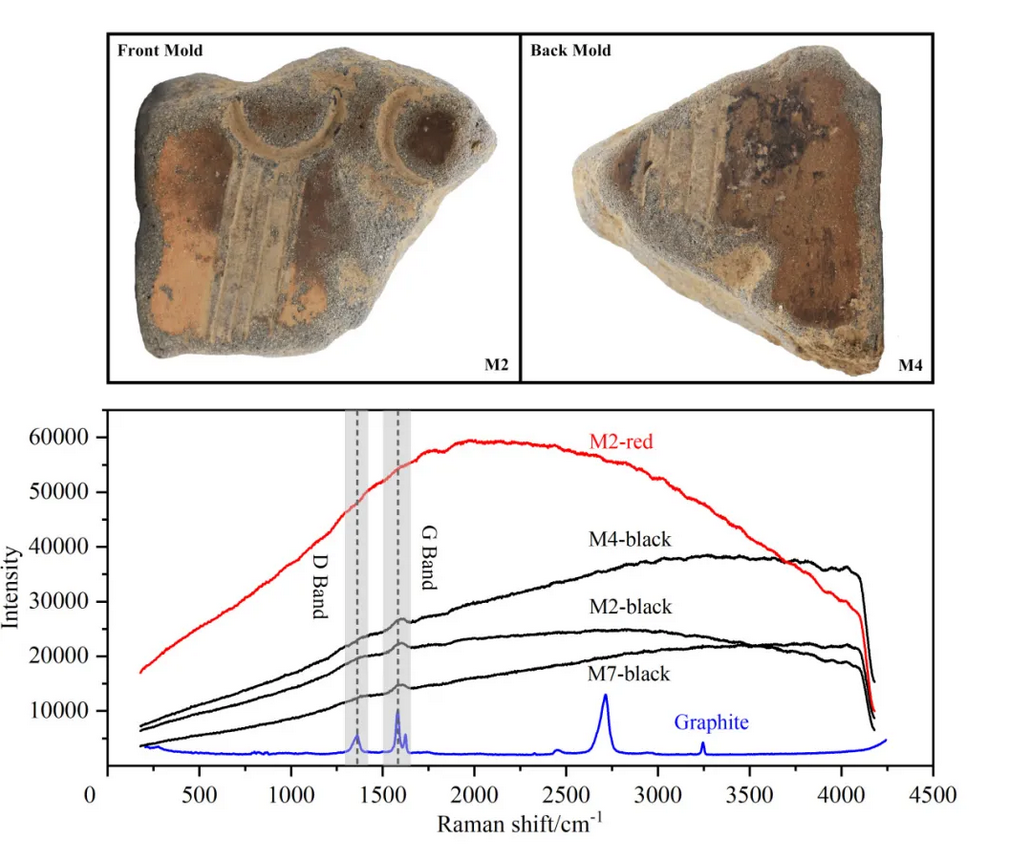

Mold

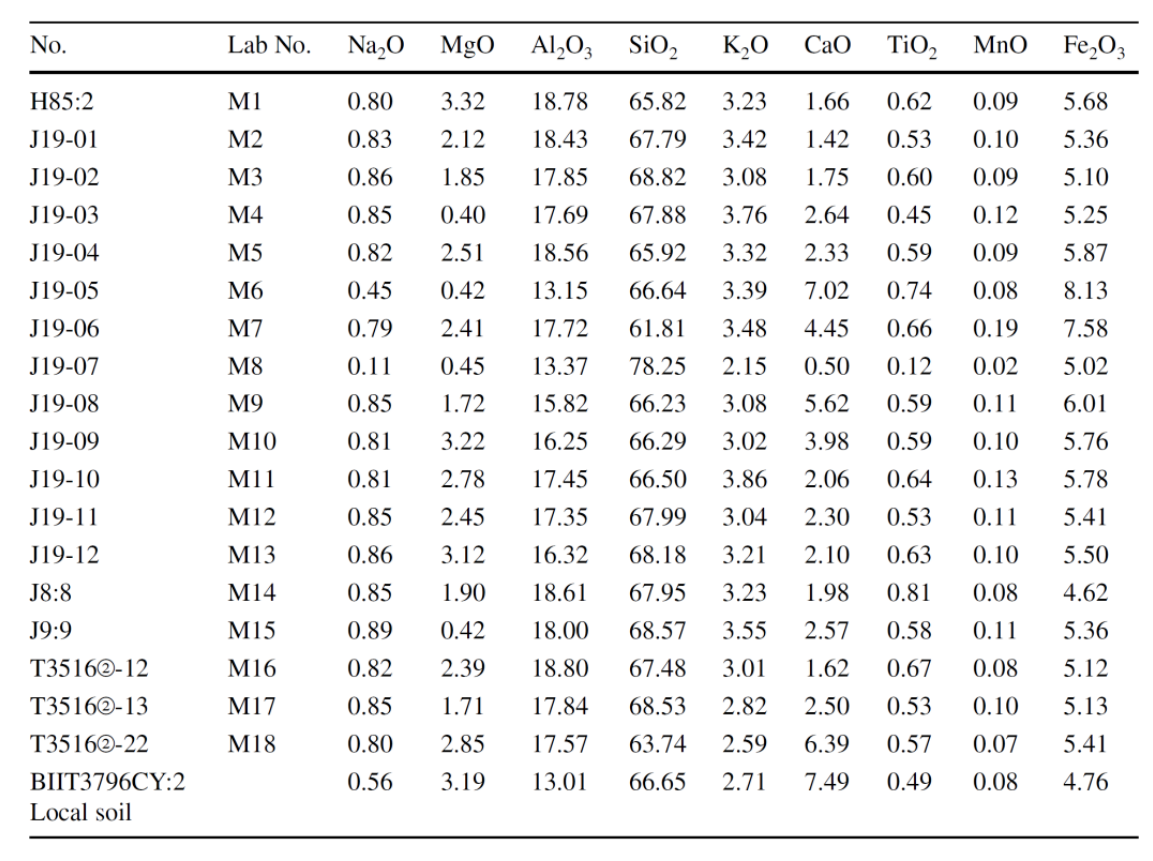

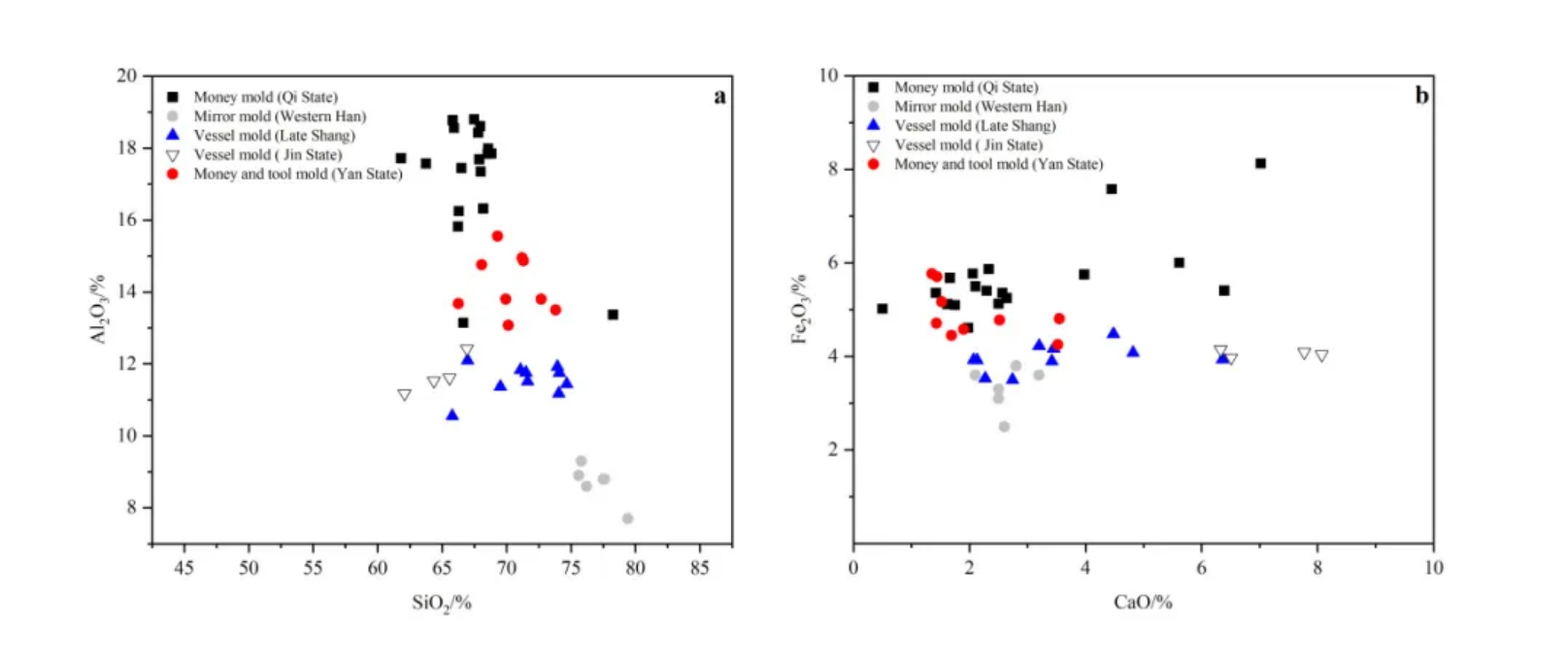

According to the data presented in Table 2, the chemical composition of the mold samples falls within the same category. Furthermore, there is minimal variation in the chemical composition between front molds and back molds. The bulk chemical composition of mold samples exhibits an average content consisting of 67.46% SiO2, 5.67% Fe2O3, and 17.20% Al2O3. Microscopic observation shows that all the mold samples are gray pottery mixed with plenty of fine and uniform silts (Fig.3). Although certain back molds still exhibit visible clay particles of significant size, none of the mold samples contain any apparent plant inclusion. In comparison to the local native soil, the primary components of silt found in ancient riverbeds exhibit similarities to mold samples. However, a notable distinction arises in the significantly higher concentration of calcium oxide (CaO) in the local soil, suggesting that the raw materials of mold may originate from the local native soil but have undergone enhancements.

Table 2 Bulk composition (wt%) of pottery mold samples analyzed by EDXRF

Fig. 3 Histogram of bulk compositional results of pottery mold (Front mold: M2/M5/M7/M9/M13; Back mold: M3/M4/M6/M8/M10/M11/M12)

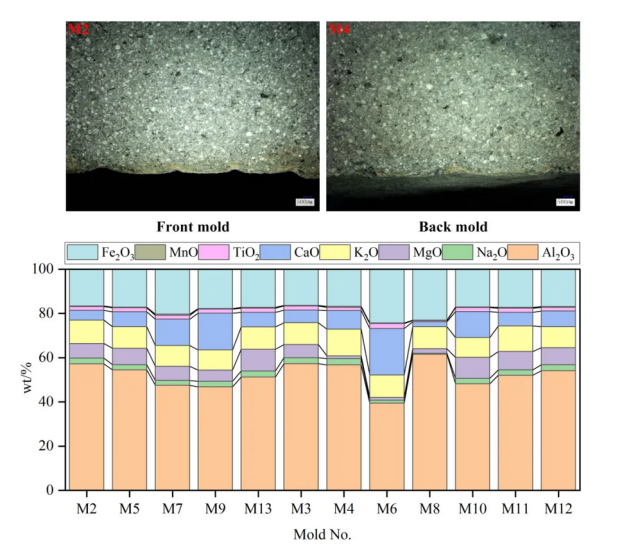

No matter the front mold or the back mold, a thin and light layer is present on the surface of the casting channel of the mold. Specifically, the presence of gray-black or black layers on the surface of the mold can be identified as intentional coatings for parting. A preliminary investigation using a Raman spectrometer was performed (Fig. 4), which confirmed the presence of Raman peaks of carbon corresponding to the D-band (1371.4 cm-1) and G-band (1599.4 cm-1) in the black layer observed on the surface of mold sample. The presence of these two distinct peaks in the Raman spectrum suggests that the black layer observed on the mold surface likely composed of carbon black, which shares similarities with graphite-like carbon materials such as graphite, carbon black, and active carbon (Fitzer et al. 1987).

Fig. 4 Raman spectrum results of surface coating on the cavity of pottery mold

Slag

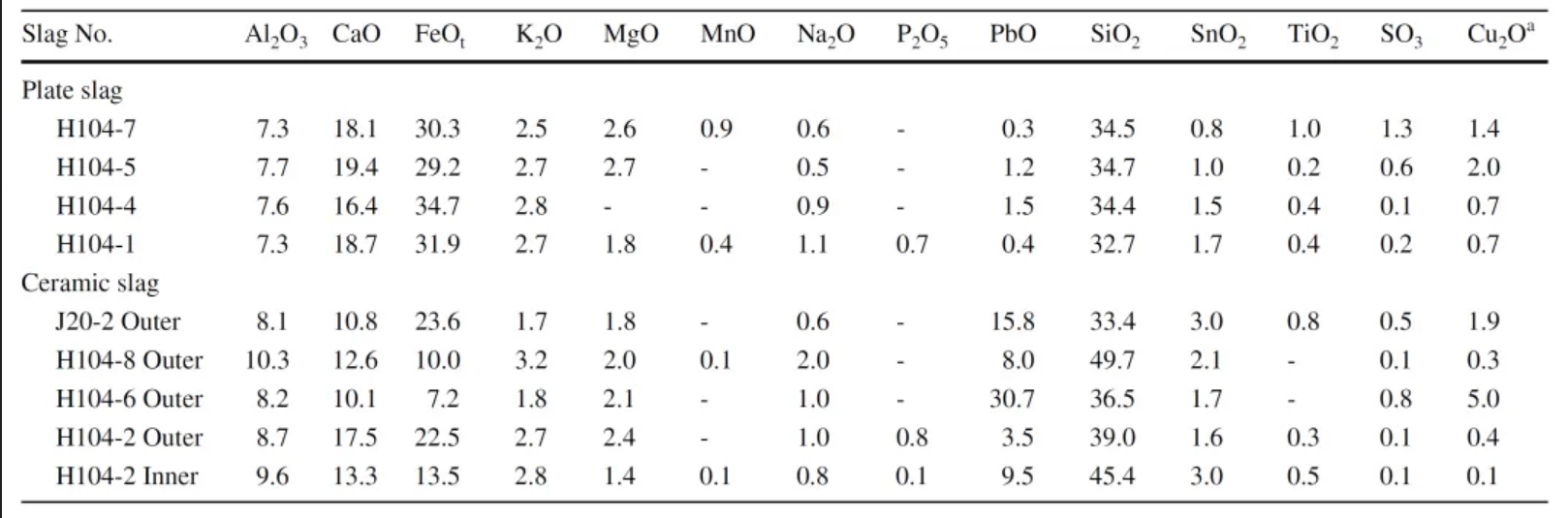

Table 3 displays the SEM-EDS analysis results conducted on the slag samples. Oxide compositions are given in average values of several small areas (120×80μm2) and normalized to 100 wt% without copper. FeOt is the total iron as FeO. Cu2Oa is the original copper content prior to normalization. Both iron and copper are expressed as low-valent oxides, and the cuprous oxide is deducted for normalization. The findings indicate that the composition of the slag matrix conforms a typical FeO-SiO2-CaO ternary system. In comparison to the ceramic slags adhered to the blowpipes, it is evident that plate slags with a higher degree of vitrification exhibit high levels of calcium, low levels of aluminium, and potentially even higher iron oxide content exceeding 30%. This observation suggests that the formation of these plate slags involves the addition of a greater quantity of basic oxide (CaO) during the smelting process (Bachmann 2016). The ceramic slags adhering to the blowpipes typically exhibit higher concentrations of lead and tin, whereas the iron oxide content is noticeably lower compared to the plate slag, typically falling below 15%.

Table 3 Matrix composition (wt%) of slag samples analyzed by SEM-EDS

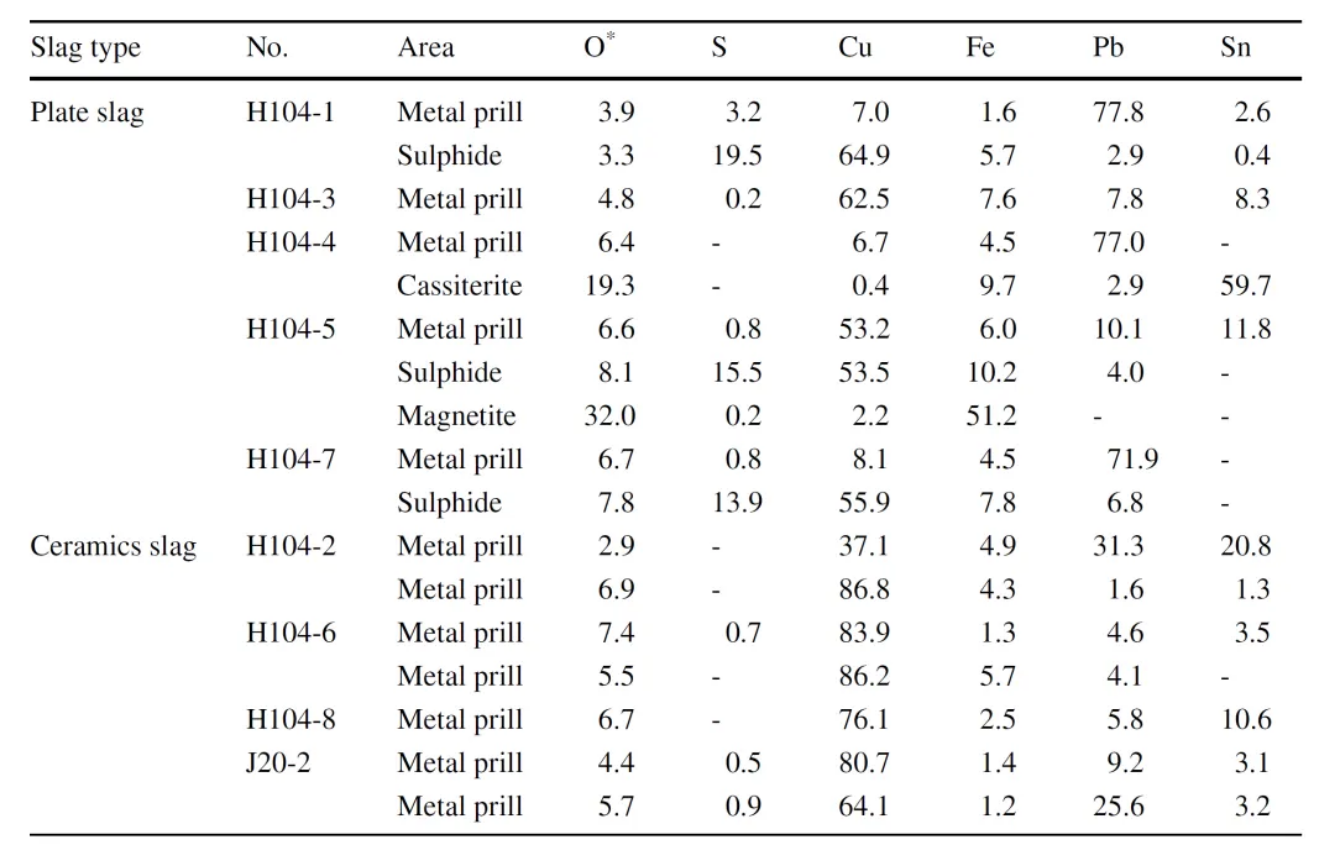

The plate slags contain a significant amount of fayalite and matte (Table 4) (CuFePbS). Within these slags, metal droplets of varying sizes are frequently found to be seriously segregated and often wrapped inside the matte (Fig. 5). For example, the plate slag (H104-1) contained a matte particle measuring 500 μm in diameter, inside which a metal droplet with a diameter of approximately 150 μm is wrapped in. Furthermore, it is evident that plate slag (H104-4) contains a greater quantity of magnetite, while the matte phase is found exclusively at the outer rims of the metal droplets. Plate slag (H104-4) has a notable abundance of cassiterite crystals, suggesting their introduction during the subsequent stage of smelting or, more plausibly, alloying.

Table 4 Inclusion composition (wt%) of slag samples analyzed by SEM-EDS

Fig. 5 BSE photos of plate slag samples

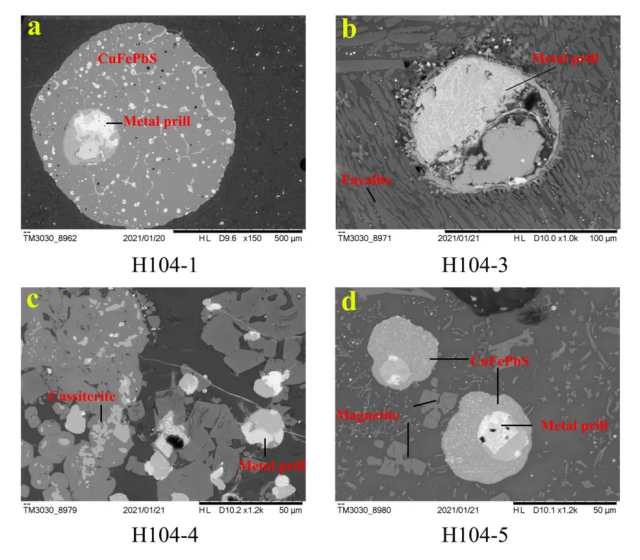

The ceramic slag adhered to both the inner and outer surfaces of the blowpipes contains magnetite, cuprite, and other phases, indicating the presence of an oxidizing atmosphere (Fig. 6). The primary metallic inclusions inside the inner slag consist of coarse copper with a high iron oxide content, while the primary metallic inclusions within the outer slag are mainly bronze. An abundance of casstierite crystals are observed in the outer slag of blowpipe (H104-2), whereas the inner slag predominantly consists of bronze particles with low content of iron and tin. Similarly, the outer slag of the blowpipe (H104-6/J20-2) contains many skeletal cassiterite crystals and lead-rich phases, whereas the inner slag of H104-6 consists of a significant quantity of coarse copper droplets. Based on the analysis of slag types, slag phases, matrix composition, and formation atmosphere, it becomes evident that these two types of slag should be tapped in different stages of the minting process (Hauptman 2020).

Fig. 6 BSE photos of ceramic slag samples

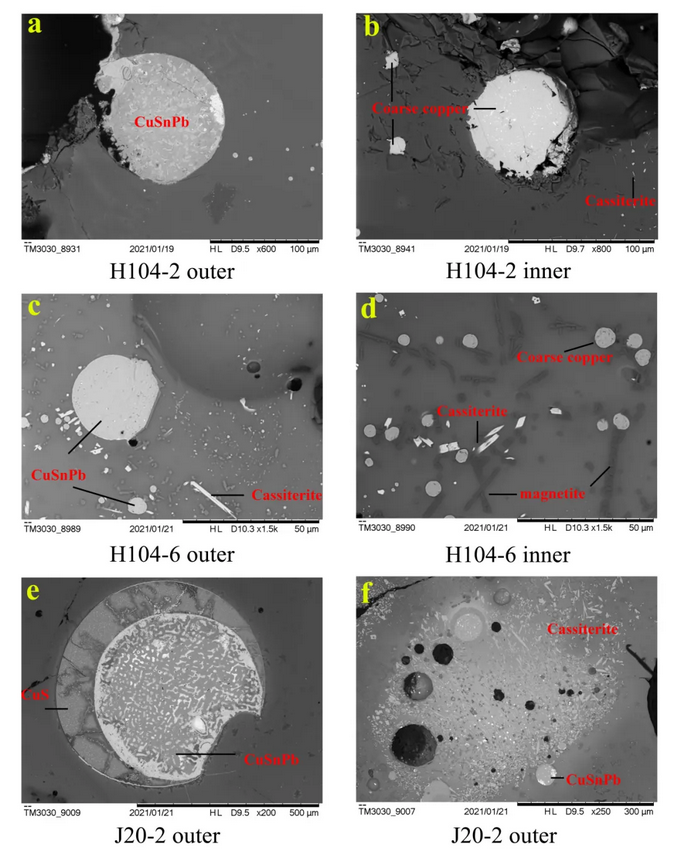

Lead Isotope analysis

The cavity surface of mold samples mostly remained molten metal with high lead content, which can be used for lead isotope analysis to reflect the resource characteristics of the minting industry. As shown in Table 5, the 207Pb/206Pb ratios of mold samples are concentrated between 0.907 and 0.911, while the 207Pb/206Pb ratios of slag samples are dispersed between 0.893 and 0.931, therefore the lead isotope ratios of slag and mold samples belong to the same kind of lead with high 207Pb/206Pb ratio. According to the published alloy composition data of Qi Knives, it can be clear that metal resources with this kind of lead isotope ratios should indicate lead ores. Furthermore, the lead resources used in the casting process are the same as those used in alloying process, therefore it is clear that these slags, molds and metal remains unearthed in this site all belong to minting remains of Kinfe money of Qi state.

Table 5 Lead isotope analysis results of minting remain samples

Discussion

Piece-mold technology

The advancement of piece-mold casting technology in ancient China can be attested to the Sui and Tang Dynasties. Prior to the Sui and Tang Dynasties, the minting industry exclusively relied on the utilization of durable molds, including pottery, stone, and metal molds. Subsequently, sand casting technique has emerged as the predominant method employed in the minting industry (Zhou et al. 2022). The key to making pottery mold in ancient China is to select suitable raw materials and processing technology to control the proportion of clay and silt so as to meet the casting performance of plasticity, fire resistance, air permeability and filling capacity. Since the Lower Erligang period, it has been observed that the SiO2 content in pottery molds is significantly higher compared to that in pottery utensils. This disparity can mostly be attributed to the intentional inclusion of well-sorted silt throughout the mold-making process. The majority of scholarly investigations indicate that the raw materials of mold during the Shang and Zhou Dynasties in north China mostly corresponded to loess soil, which was subjected to a refining process involving the removal of coarse pebbles and the addition of silt (Liu 2018). During the Han Dynasty, an innovative technique involved the use of rice husk ash were introduced in the production of Linzi mirror molds. This addition served to augment silt content in the form of amorphous SiO2, resulting in a significant enhancement of the flexibility and casting performance of the pottery mold (Cui 2020).

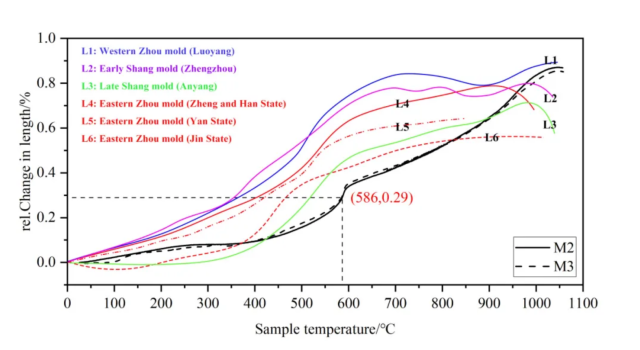

The chemical composition of these mold samples unearthed in Linzi in the late Warring states period is very close to ordinary gray pottery unearthed in Shandong Province (Li 1996), with the Al2O3 content is as high as 17% and the SiO2 content is between 64% and 69%. In comparison to the pottery molds from the pre-Qin period and the mirror molds during the Han Dynasty discovered in Linzi (Fig. 7), the Al2O3 content of this batch of molds is significantly higher. Additionally, the SiO2 content falls within the range observed in the pottery molds from Houma and Yanxiadu during the Warring states period. It seems that pottery molds of Qi Knife with low content of silts are not suitable for bronze casting, but it is worth noting that these molds actually exhibit fine fire resistance and very low thermal expansion. According to the data presented in Fig. 8, it can be observed that the thermal expansion curve of these mold samples exhibits abrupt changes in slope at temperatures ranging from 350 to 400℃ and approximately 586℃. These distinct changes suggest the occurrence of phase transitions within these specific temperature ranges. Furthermore, the thermal expansion observed at approximately 580℃ corresponds to a phase transition of quartz, wherein it transforms from its β phase (cubic system) to the α phase (hexagonal system). The molten phase remains absent even at temperatures exceeding 800℃. In contrast to the pottery molds from the pre-Qin period (Fig. 8), these knife money molds exhibit a significantly lower thermal expansion rate throughout the temperature range of 400 to 800 degrees. Hence, it is plausible that the selection of this kind of pottery mold for knife money production was primarily driven by the objective of ensuring casting stability (Lian 1996). This choice is particularly justified due to the frequent reuse of these molds and the absence of a requirement for intricate patterns. Furthermore, it is imperative that the minimum firing temperature of these molds is sufficiently elevated to ensure minimal gas generation and optimal dry strength, while also attaining the necessary temperature for preheating prior to bronze casting.

Fig. 7 a: Scatter diagram of the content of SiO2 and Al2O3 in the pottery molds, b: Scatter diagram of the content of CaO and Fe2O3 in the pottery molds (Date from (Tan 1986a and Lian 1992 and Liu et al. 2005 and Jin et al. 2016))

Fig. 8 Thermal expansion curve of pottery mold samples at 5K/min heating rate (Date from (Tan 1986b and Lian 1992))

Smelting and Alloying technology

The plate slags have a significant iron oxide content of up to 30% in matrix, and a substantial presence of matte particles (CuPbFeS), which are all regarded to be associated with smelting slag process. It can be speculated that the plate slag (H104-1) of a bigger size should be tapped during the initial phase of the smelting process and the plate slag (H104-3, 4, 5, 7) of a smaller size should be tapped during the latter stages of smelting. The matrix of plate slag also exhibits some phases that are rich in lead and tin. The metallic droplets contained in the plate slag exhibit significant segregation, with an average iron oxide content of 3% (Table 4). The iron oxide content of the ceramic slag adhered to the blowpipe appears to be relatively low. The inner slag predominantly consists of larger coarse copper droplets, whereas the outer slag primarily consists of bronze droplets. The above analyses indicate that the current batch of plate slag is likely the slag that was tapped during the intermediate stage between smelting and tin alloying. This suggests that the smelting process involves the rough smelting of sulphur-containing copper-lead ore, and potentially even the direct addition of tin material for alloying prior to thoroughly smelting (Dungworth 2000 and Dai et al. 2021). The observed composition features of the ceramic slag adhered to the blowpipe suggest the possibility of a separate process including the full refinement of matte prior to the introduction of tin and lead materials for alloying.

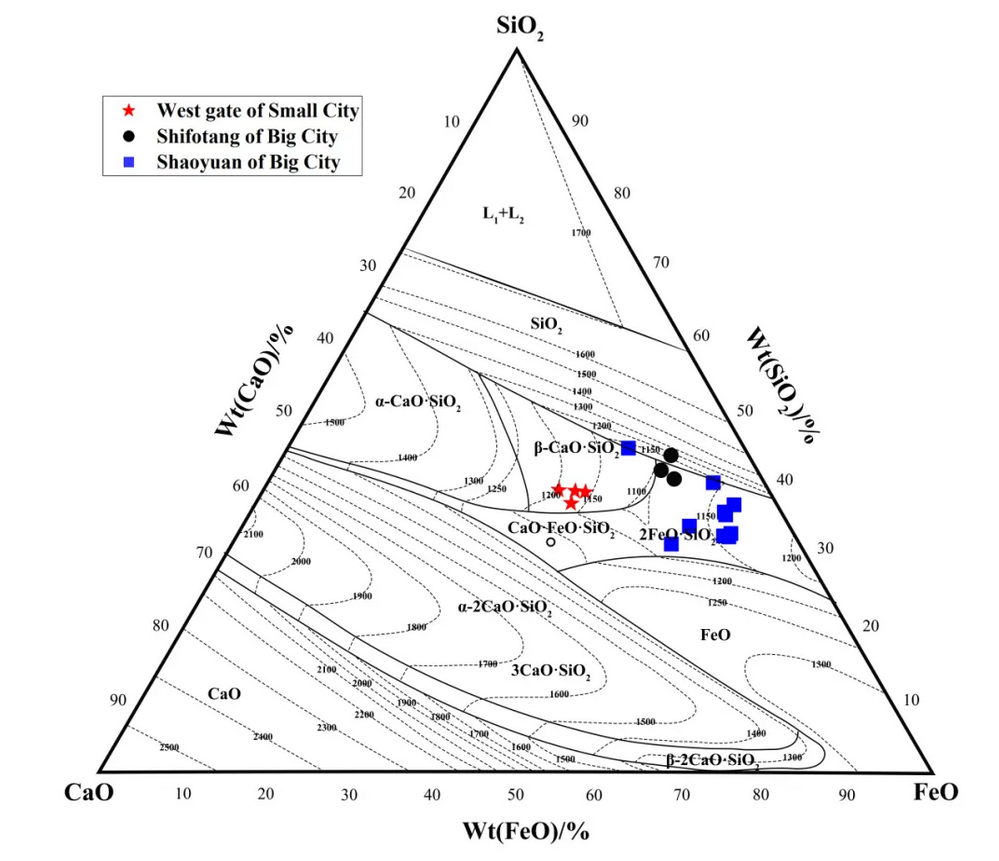

Based on the bulk chemical composition of slag matrix (Table 3), we can calculate the silicate degree of slag samples unearthed outside the west gate of Linzi city site. Slag silicate degree refers to the ratio of the sum of oxygen content in acidic oxides to the sum of oxygen content in alkaline oxides (Fu 1993). The acidic slag contains high amounts of SiO2 and Al2O3 which contribute to increased viscosity and reduced thickness of the slag. A less acidic or basic slag contains more basic oxides like MgO and CaO, which makes the slag less viscous considering that they can cause quartz to dissolve at lower temperatures (Fu 1993). The results indicate that the silicate degree of plate slag ranged from 1.0 to 1.07, whereas the silicate degree of ceramic slag ranged from 1.25 to 2.04. This difference can be attributed to the higher concentration of CaO contained in the matrix of plate slag. Modern smelting technology usually requires the silicate degree of slag to be maintained in the range of 1.0 to 2.0 (Fu 1993). The examined slag samples obtained from various remains in Linzi city site predominantly fall within this specified range. This observation suggests that during the late Warring states period, metallurgical craftsmen in the Qi state potentially attained technology in smelting sulfide ore and adding alkaline earth oxides as slagging agents.

Based on the FeO-SiO2-Al2O3 ternary phase diagram (Fig. 9), it can be observed that the smelting temperature of plate slag is approximately 1150℃, a temperature close to the formation temperature of kirschsteinite. This finding is in strong agreement with the smelting temperature recorded for slags discovered in both Shifotang Village and Shaoyuan Village. Nevertheless, it is evident that the smelting temperature of the ceramic slag adhered to the blowpipe is notably higher, and certain samples tend to be in tridymite area. This observation could potentially be attributed to the more effective heating process. As the slag itself is a complex multi-component system, any added oxide will reduce the actual smelting temperature, and the actual smelting temperature of the slag should be lower.

Fig. 9 Ternary phase diagram of FeO-SiO2-CaO system of slag samples unearthed from some metallurgical sites in Linzi city site (Date from (Du et al. 2012 and Li et al. 2014))

The majority of metal droplets contained in the slag exhibit incomplete alloying and significant segregation. While these metal droplets may not provide a comprehensive representation of the alloy composition in the ultimate product, preliminary inferences of alloy types in the final product can be made regarding the presence of lead-tin bronze, tin bronze, and lead bronze (Li and Hong 1995). The metal droplets present in the outer slag of the blowpipe predominantly consist of bronze, with certain droplets containing up to 30% lead and around 5% tin in content. Pioneer studies conducted by Zhou and Wang have demonstrated that the knife money of Qi state primarily consisted of ternary alloys composed of copper, lead, and tin (Zhou et al. 1992; Zhou 2004; Wang and Wang 2014). The chemical composition of the early four-character knives closely resembles that of the five-character knives, with a predominant tin percentage exceeding 10% and lead level predominantly below 15%. The composition of the three-character knife has resemblance to that of the round money, with a lead concentration of up to 40% and a tin content below 5%. Obviously, the composition characteristics of the inclusion droplets in the ceramic slag samples are very consistent with the alloy composition of the three-character knife. We can further confirm that all of these metallurgical remains have a close relationship with the production of “three-character knife” or “Qi da dao” in the late Warring states period.

Lead resource transformation of minting industry in Qi state

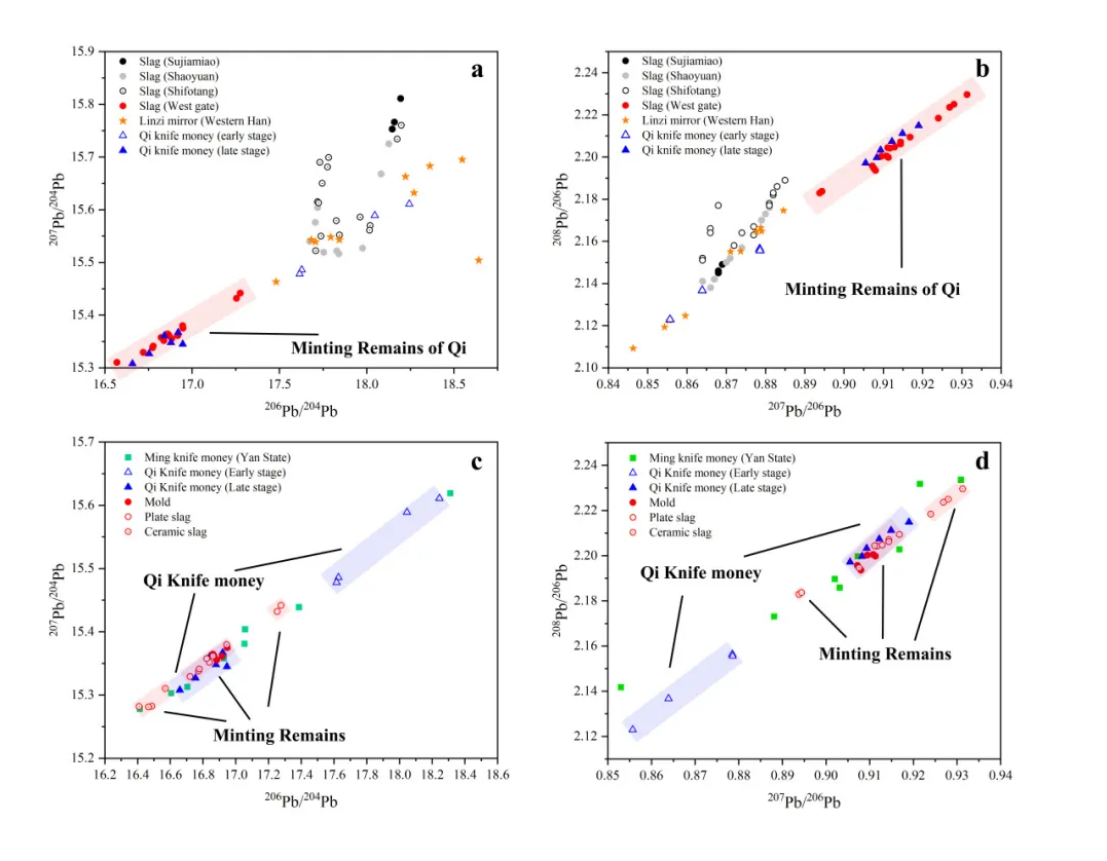

Jin previously observed that the lead isotope ratios of four-character knives and five-character knives bear resemblance to those observed in Central Plains coins during the early and middle warring states period (Jin et al. 1993). However, three-character knives and round money of Qi state in the late Warring states period exhibit distinct lead isotope ratios characterized by high 207Pb/206Pb ratio. Notably, previous archaeological investigations (Cui et al. 2021) conducted in the Shandong Peninsula did not yield any metallurgical remains indicative of this kind of lead (Fig. 10a& 10b). The minting remains unearthed outside the west gate of Linzi city site exhibit a striking resemblance to the lead resources employed in Qi knife money. Furthermore, these minting remains represent the earliest related examples of archaeological smelting remains discovered within the Shandong Peninsula. The utilization of lead resources with high 207Pb/206Pb ratio was initially observed in the bronzes as early as Erlitou Phase IV and Erligang Lower period (Jin 2008). Additionally, it was prevalent in the knife money that circulated in the vicinity of the Bohai Sea during the Warring states Period (Jin et al. 1993 and Zhang 2020). However, it is important to note that these bronze groups were not directly related and likely originated from different sources. By the Western Han Dynasty, this kind of lead resources was no longer used in the bronze mirrors unearthed in Linzi city site (Cui et al. 2009). Our investigation of lead isotope ratios has provided more insights into the dramatic changes in the supply of lead resources utilized by Qi knives during the Warring states period (Fig. 10c and d). The synchronization between the evolution of lead resources and the changes in alloy composition suggests a significant transformation in the minting industry of Qi state during the Warring states period.

Fig. 10 Comparison of lead isotope ratios between Linzi metallurgical remains and knife money (Date from (Jin et al. 1993 and Cui et al. 2021))

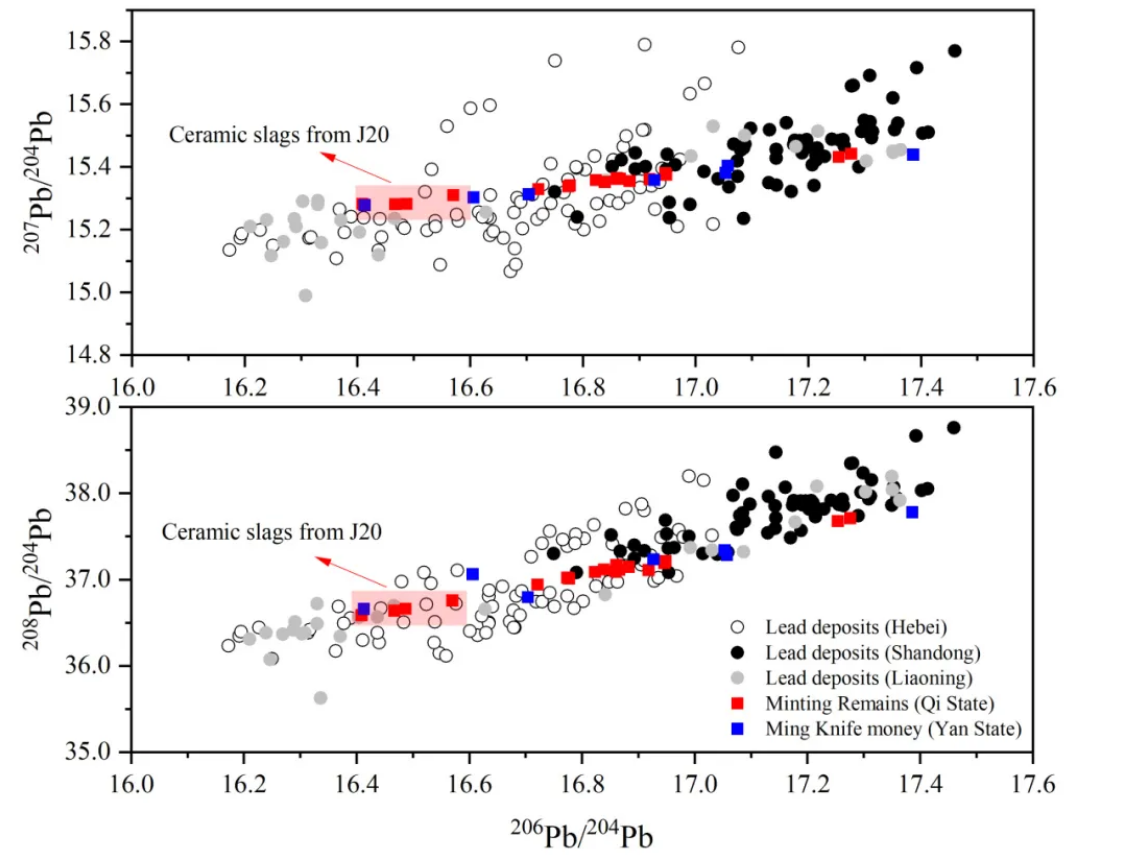

As a matter of fact, Ming knives in Yan State had already used lead resources with a high ratio of 207Pb/206Pb in the middle of the Warring States Period, which is much earlier than that in Qi State. There is a prevailing belief that the lead resources with high 207Pb/206Pb ratio are predominantly sourced from the eastern region of Liaoning Province, historically within the jurisdiction of the ancient Yan state (Jin et al. 1993 and Lin et al. 2022). Based on the comprehensive geological data presented in Fig. 11, it can be observed that lead resources with high 207Pb/206Pb ratio are actually extensively spread in the vicinity of the Bohai Sea (Hsu and Sabatini 2019). However, notable regional variations are also evident. Lead resources with high 207Pb/206Pb ratio located in the ancient Qi state usually have a higher content in thorogenic lead, whereas this kind of resources located in the ancient Yan state tend to have a generally high uranogenic lead content. Lead ores with medium content of radiogenic lead isotope ratios were discovered until now only in the Jiaodong area of Shandong Province (Li 2012) and the eastern area of Liaoning Province (Jiang et al. 1992). At present, the lead isotope ratio of Qi knives in the late Warring states period is roughly distributed in a similar range, which is very consistent with the characteristics of lead ores in Jiaodong area. Nevertheless, it is evident that the lead isotope ratios observed in some ceramic slags unearthed from J20 exhibit a notable uranogenic lead content, closely resembling the lead isotope ratios observed in Yan Knives and lead deposits found in the eastern region of Liaoning Province.

Fig. 11 Comparison of lead isotope ratios between Linzi metallurgical remains and peripheral lead deposits (Deposits data from (Hsu and Sabatini 2019))

The reconsideration of the utilization of lead resources in the minting industry of Qi state should be undertaken within the context of its historical background. In the year 386 BC, the house of Tian fully replaced the house of Jiang as rulers of Qi state. Following the ascension of Taifu Tianchen to the throne of Qi state, Qi state probably newly developed and utilized lead resources in Jiaodong area for bronze-casting industry, especially the local exploitation of lead resources with high 207Pb/206Pb ratio promoting the production and circulation of the three-character knives and round money in the late Warring states period. During the late Warring states period, a series of conflicts arose between Qi state and Yan state, particularly the occupation of Qi's capital by Yan state in 284 BC. This event resulted in a stagnation of the minting industry in Qi state (Wang 1988). The discovery of the Ming Knife mold in Linzi directly showed that Yan state had cast their own metal money in Linzi during this period, and Qi state was also shortly popular with a kind of knife money with similar shape to Ming Knife of Yan state (Chen 2001). Based on the above geological and historical background, we can suggest that some ceramic slag samples with the characteristics of high uranogenic lead, might not have appeared until Yan's conquest over Qi.

In summary, Linzi had significant growth and development as a metropolis during the Warring states period, which was marked by the advancement of its commodity economy corresponding to the flourishing minting industry. The study presented above demonstrates that the standardized coinage production during the Tian Qi period may be seen as a strategic approach to monopolize the coinage rights of knife money and even round money. The implementation of an active monetary policy by Qi state has significantly facilitated the growth of domestic industry and commerce. Additionally, it has fostered increased economic interactions between Qi state and other states, thereby contributing to the economic prosperity and social stability of Qi state. Until Emperor Qin Shi Huang conquered the various "warring states" and unified China in the year 221 BC forming the Qin dynasty, the Ban Liang coin was finally introduced to standardize all forms of currency as a part of a broader plan to unify weights and measures.

Conclusion

The minting industry of Qi knives in the late Warring states period perfectly complemented each other from the aspect of production background. Molds of Qi knife are made of grey pottery with moderate silt and clay content in order to ensure low thermal expansion rate. There is a uniform coating on the surface of the mold for parting. These are specially selected molding technology based on the castability of lead-rich alloy for controlling shrinkage and standardizing size. There is a process of smelting sulfur-containing copper-lead ore to obtain matte and adding tin material for alloying, and perhaps there is a process of adding tin and lead raw materials respectively to alloy after refining matte. Such smelting technology can greatly improve the production efficiency of copper-lead alloy.

Our study firstly confirmed the use of lead resources with high 207Pb/206Pb ratio in the minting remains in Shandong Peninsula in the late Warring states period. The change of the lead resources in Qi knives was synchronized with the change of their alloy compositions. This kind of lead resources is very consistent with the characteristics of lead ores in Jiaodong area, but some samples obviously have higher uranogenic lead, which is more consistent with the lead ores in Liaodong area. It is not excluded that the lead resources with high 207Pb/206Pb ratio originally used in Qi state came from local areas, and some high uranogenic lead resources may have been brought in after Yan state occupied Qi state.

The above analysis reveals that the production of Qi knives in the late Warring states period is highly standardized in terms of molding technology, smelting technology, alloying technology and ore source. The standardized coinage production is the intuitive embodiment of monopolizing the coinage right and developing the commodity economy during the Tian qi period (BC386-BC221).

-

-

-

-

-

地址:北京市海淀区颐和园路5号

邮编:100871

邮箱:webmaster@pku.edu.cn

-

版权所有©北京大学

京ICP备05065075号-1

京公网安备 110402430047 号